Pop-up Civilization: Protocols & Resilience-Tech for Rewilding Agency

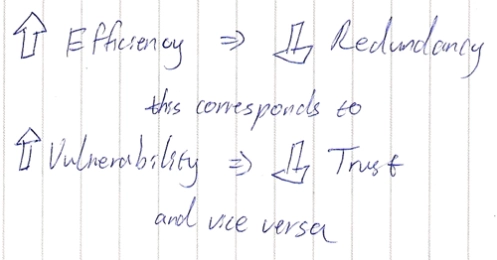

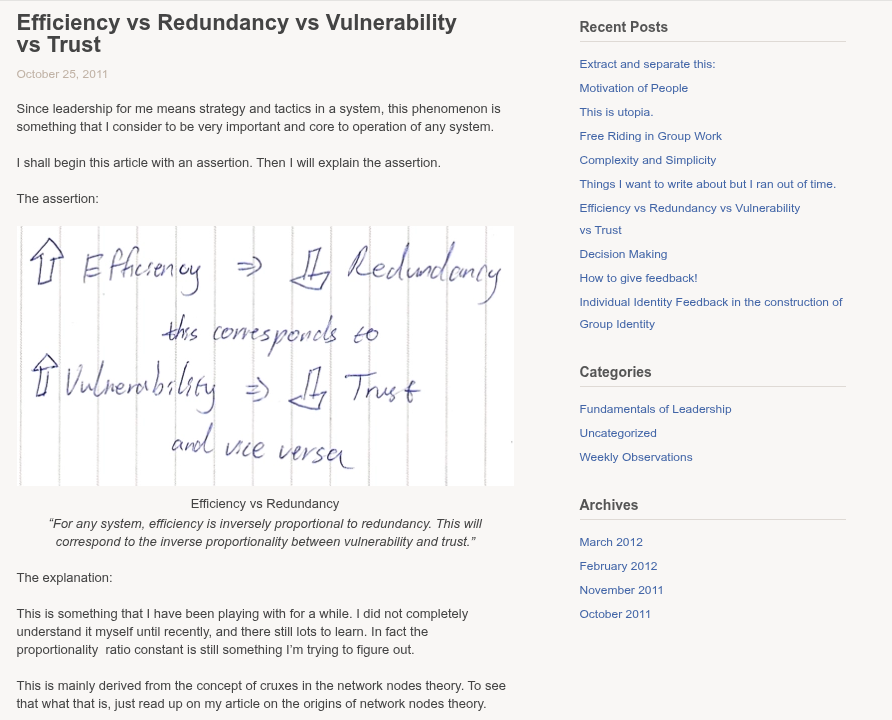

In 2011, as part of an interdisciplinary course at the Australian National University (VCUG20021), I wrote an article about the relationship between efficiency, redundancy, vulnerability, and trust. That post is still online2. The basic principle was focusing on efficiency often meant squeezing out redundancy and buying systemic fragility. Fifteen years later, those notes came back to audit our own systems that we've been building, but the pattern is fractally repeated across our entire technological civilisation.

Whether it is information or operational technology, fragility is systemic. A transactional incentive stack optimized for neat dashboards and KPI theater drove just-in-time supply, platform centralization, and brittle dependencies. In IT, knowledge was open but platforms enclosed. In OT, platforms are less centralized, but knowledge, integration, and supply are gated behind vendors, institutions and system integrators.

Both paths hollow out the crucial 'missing middle' of talent: the technicians, integrators, and applied engineers who turn prototypes into reliable infrastructure and products. These are hybrid thinkers and doers. Without this layer, capability centralizes into a barbell: a few hyper-scale production giants on one end, and a long tail of hobbyists on the other. This fragile structure, lacking a broad, adaptive ecosystem, is then shattered by real-world shocks: pandemics, port closures, energy spikes, sanctions, floods, brownouts. The lesson is simple: resilience isn't a vibe. It is a set of design choices, supply chains, and what still works when the internet sneezes or the maintainer goes hiking.

This post lays out a practical stack for that world. Think pop‑up civilization instead of mega‑projects: modular capabilities that communities can deploy themselves in energy, comms, making, and logistics. We start with solar because it forces the whole conversation: sourcing, manufacturability, numbers, and why verifiable outcomes (receipts) are the missing coordination layer that ties physical work to capital and incentives so the missing middle actually gets built and paid.

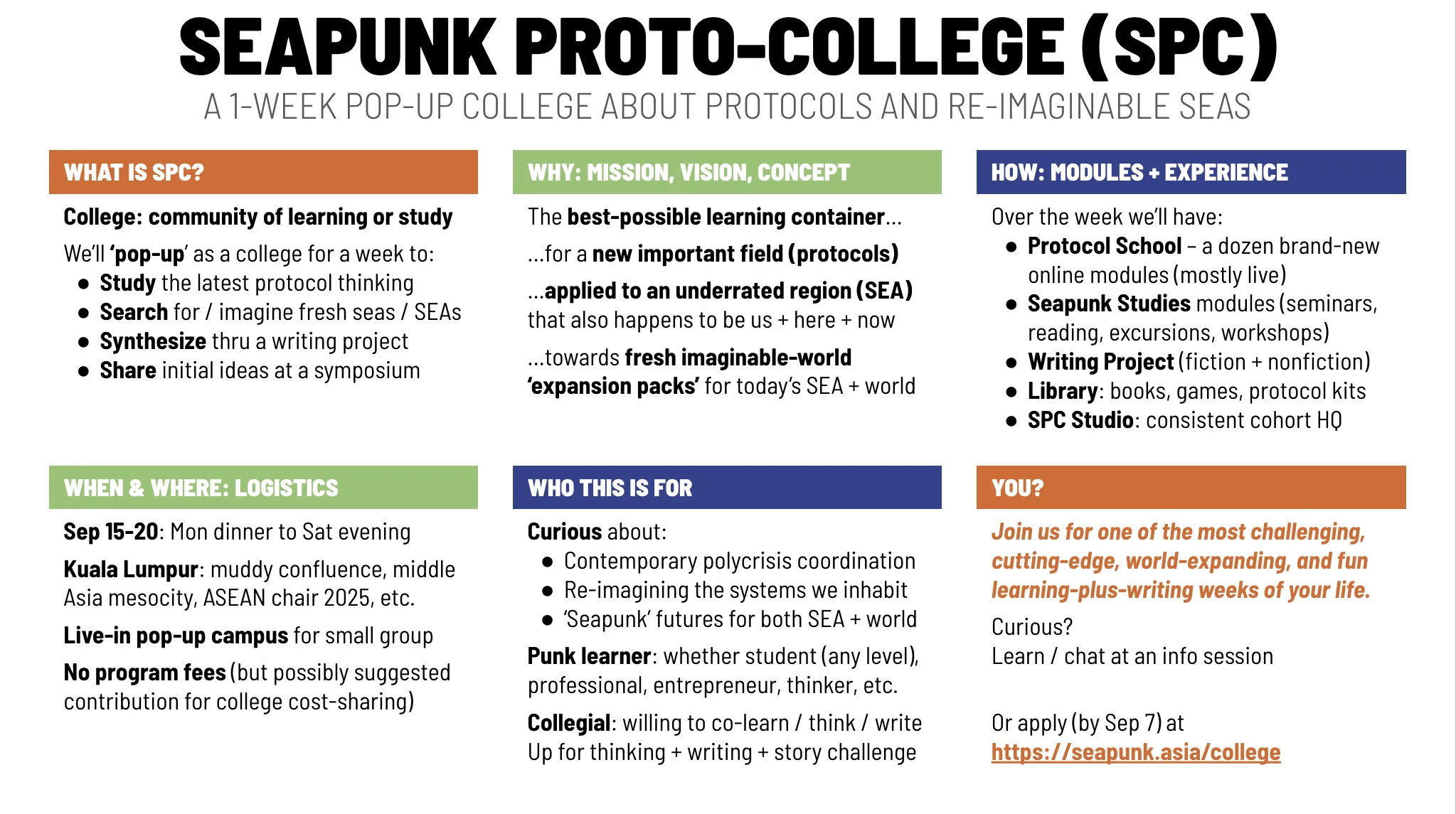

We are presenting this post's content as part of the first in-person pop-up protocol study group in Kuala Lumpur, Malaysia, called Seapunk Proto-College, itself an experiment towards decentralizing education. It was later also presented as during a Desci World meeting.

Efficiency vs Redundancy

We're starting to shift from worshiping hyper-efficiency to building resilience, but let's be precise: the pendulum has barely begun to swing. In mid-2025, the center of gravity for our critical systems still sits with a handful of compute, cloud, fab, and discovery hubs. "Resilience" remains mostly narrative unless it shows up in open interfaces, procurement terms, and operational drills.

This isn't a theoretical risk; it's a reality laid bare by a series of spectacular, real-world failures that revealed the two parallel paradoxes driving our systemic fragility:

- The IT Paradox: The foundational knowledge of IT is more accessible than ever, yet the economic reality is one of hyper-centralization. This was made painfully clear during the 2021 AWS outage, where a single failure at a US-East server farm bricked smart homes, robot vacuums, and doorbells across the globe, these are cloud connections that are entirely unnecessary. We have open protocols, but we've built a world where you can't turn on your own lights if a distant server trips. This is the new digital enclosure: open in principle, but closed and fragile in practice.

- The OT Paradox: The world of operational technology is less centralized at the platform level, but the knowledge and supply chains are highly gated. This was the story of the great semiconductor shortage. Automotive production lines didn't stop for lack of shipping containers; they stopped for a lack of dollar-chips from a handful of foundries. It was a failure born from just-in-time inventories coupled with a supply chain so specialized and opaque that no single actor had a complete picture. This is the other enclosure: fragmented in platform, but closed and fragile in practice.

These twin paradoxes, stress-tested by events like the Suez Canal blockage (a physical chokepoint) and the Texas power grid collapse (an infrastructure monoculture), have produced the same outcome: a barbell structure that hollows out the missing middle. This isn't just an economic abstraction; it's the tangible absence of the technicians, integrators, and applied engineers who can turn prototypes into reliable products, integrate multi-vendor systems, and repair them when they break.

In Austin, during the February 2021 freeze, this wasn't an abstract theory. Neighbors pooled resources in the few homes that kept power. Others didn't make it; the official state-wide death toll was 246. This is what happens when resilience is outsourced. The incentives for a centralized provider to hold spare capacity for extreme events are weak, so when the shock arrives, it's the community's own margin that decides the outcome.

The math is unforgiving. In a stable system, optimizing for the average (efficiency) wins. In a volatile system, optimizing to control variance (resilience) and avoid ruin wins.

-

The Volatility Penalty: For any system with compounding returns (like capital, or operational uptime), the long-term growth rate is penalized by variance. Higher volatility directly reduces your time-averaged growth, even if the average return is the same.

Time vs. average. For compounded outcomes, maximize :

Same mean, higher variance lower time-average growth.

GBM exact: if , then

-

The Kelly Criterion: The optimal strategy for maximizing long-run growth in the face of uncertainty is to never bet the whole farm. The more volatile the system, the more margin you must hold in reserve.

Kelly (binary odds ):

Merton (continuous log-utility):

-

Ruin is an Absorbing State: A system optimized for efficiency with a non-zero probability of catastrophic failure will, given enough time, eventually fail. Resilience is the strategy of avoiding ruin first, and optimizing for efficiency second.

Ruin hazard: if per-period ruin prob is ,

Roadmap towards Practical Resilience

True resilience, therefore, is not about nostalgia or a return to a simpler time. Resilience is capability density in the missing-middle. It is about fundamentally re-architecting our systems for optionality and sovereignty. This means shifting our design principles:

- From Platforms to Protocols: We must prioritize open interfaces, data portability, and the right to substitute components without being locked into a single vendor's ecosystem.

- From Centralized Control to Edge Capability: We must build systems that can operate autonomously, with graceful degradation, when disconnected from the central cloud.

- From Tenancy to Ownership: We must empower users and communities with control over their own infrastructure, data, and devices.

This isn't an abstract manifesto. It's a practical engineering roadmap. At Matrix AI, our mission is to help build the tools and protocols that bridge the gap between these principles and on-the-ground reality. The goal isn't to boil the ocean or rebuild the entire industrial world; it's to enable the creation of a "pop-up civilization stack", a ladder of modular, portable capabilities that a community can deploy and own themselves.

This ladder has four essential rungs, built in sequence:

- Secure Local Energy: First, you establish energy sovereignty.

- Establish Resilient Comms: Then, you light up communications.

- Enable Local Making & Sensing: Next, you gain the ability to build and measure.

- Build Sovereign Logistics: Finally, you move things on your own terms.

We are starting with the first and most fundamental rung: Energy. Everything else depends on power. If you want local agency, you begin by securing a local energy source that can operate independently of the grid. Solar is the most modular, rapidly deployable, and accessible technology to achieve this. It scales from a single panel on a roof to a full microgrid, and its core components are becoming increasingly commoditized.

For a place like Southeast Asia, this isn't a theoretical exercise. Frequent brownouts, the high cost of diesel for off-grid communities, and an archipelagic geography make distributed solar a necessity, not a luxury. The climate here is both a blessing (ample sun-hours) and a curse (heat and humidity that punish poorly-engineered systems). This makes it the perfect place to focus on what actually works.

True energy sovereignty isn't just about deploying panels that someone else manufactured in a hyper-centralized, distant factory. That's just a longer, more fragile supply chain. True resilience comes from owning the means of production. This is a deliberate shift away from a society of alienated consumers and towards a society of capable producers. It reframes the debate: the goal of decentralization is not to find a "cheaper" consumer product that can compete with the hyper-efficient centralized economy. The goal is to make a producer investment. You decentralize because you want to own a piece of your own infrastructure, to have agency over the tools that power your life.

Decentralization wins by reducing rent extraction and sharing value to

producers, by structurally prioritizing antifragility and local economies of

scope over monolithic efficiency. It does not win by undercutting hyperscale on

sticker price. Return on Investment (ROI) comes from use (stacked yields,

leveraging recombination and diverse outputs), not from the panel's ex-factory

$/W. Low module prices (or low commodity prices in general) are a tactical

input, not a strategy.

This is why we must focus on technologies that can be decentralized not just in their use, but in their creation, their design, and their funding. This leads us to the concept of the microfactory, a powerful tool for rewilding agency. Instead of relying on a global supply chain for finished modules, a community or a small enterprise can use a compact, containerized production line to fabricate and repair their own solar panels on-site. This is a profound shift in capability. It increases optionality by reducing dependency on shipping, enabling faster repair and replacement cycles, and allowing for rapid iteration on designs tailored to the local environment.

Most importantly, it builds a local ecosystem of skilled technicians, the very "missing middle" our current system has hollowed out. It creates a context for tech transfer, for skills to be learned and compounded locally. This is not just about producing watts; it's about producing capability.

The question then becomes: which solar technologies are actually amenable to this kind of decentralized, producer-centric model? This forces us to look beyond just today's market leader and into the strange, new tech that offers a different set of trade-offs, not just in efficiency, but in manufacturability and accessibility.

This is why we need to compare the incumbent, crystalline silicon, with an emerging alternative like perovskites.

The State of Solar: Silicon vs. The Perovskite Wedge

Today's solar landscape is dominated by crystalline silicon (c-Si). It's a mature, bankable technology. The panels are rugged, the failure modes are well-understood, and the global supply chain, while concentrated, is efficient. For fixed, long-term installations where weight is not the primary constraint, silicon is the undisputed workhorse.

However, silicon's manufacturing process from purifying silicon to growing ingots and wafering is a high-capex, centralized affair. This is where a new class of materials, perovskites, presents a compelling alternative, not as a wholesale replacement, but as a strategic "resilience wedge."

| Factor | Crystalline Silicon (c-Si) | Perovskites (Printable Thin-Film) | The Resilience Implication |

|---|---|---|---|

| Manufacturing | High-temperature, high-capex, centralized fabs. | Low-temperature, solution-based "printing." Amenable to smaller, distributed microfactories. | Perovskites offer a path to localizing the manufacturing of PV, not just the assembly. |

| Form Factor | Rigid, heavy glass-sandwich modules. | Can be printed on flexible, lightweight substrates (like plastics) or glass. | High power-to-weight ratio. Enables rapid-deployment, portable, and weight-constrained applications (e.g., rooftops, drones, temporary shelters). |

| Efficiency | High (20-23% commercial modules). | Approaching silicon in labs. Perovskite-on-silicon tandems are already hitting >25% commercially, boosting the output of existing silicon tech. | Tandems offer an upgrade path; standalone perovskites are "good enough" for many off-grid loads. |

| Supply Chain | Highly concentrated in a few regions, creating geopolitical risk. | Precursor chemicals are more broadly available, but high-purity grades and specific halides (like iodine) have their own chokepoints. | Diversifies the material dependency away from the silicon supply chain, but introduces new chemical sourcing considerations. |

The Hard Realities for Perovskites in Southeast Asia:

The promise of perovskites is immense, but the engineering challenges in a tropical environment are non-trivial. This is where the real work of the "missing middle" comes in:

- Encapsulation is the Product: Perovskites are notoriously sensitive to moisture and oxygen. In the heat and humidity of Southeast Asia, a naive encapsulation will fail in months, not years. The real innovation isn't just the perovskite chemistry itself, but the development of robust, low-cost barrier films, edge seals, and lamination processes that can survive years of thermal cycling and UV exposure. Glass-glass encapsulation with a UV-cured edge seal is a proven starting point.

- Lead Management is Non-Negotiable: Most high-performance perovskites today contain a small amount of lead. While the quantity is minimal (grams per square meter), a responsible deployment requires a full lifecycle plan, including robust encapsulation to prevent leaching and a clear end-of-life recycling or reclamation process. This is a solvable engineering and logistics problem, not a fundamental showstopper.

- Stability over Peak Efficiency: For a resilience application, a 12% efficient panel that lasts for ten years is infinitely more valuable than a 20% efficient panel that dies in two. The focus of a local microfactory should be on process control, quality assurance, and developing a stable, reproducible "recipe" that is optimized for the local climate, rather than chasing record lab efficiencies.

Let's make a Perovskite PV Panel

Our goal is to build a hand-made, palm-sized glass mini-module that can produce a few hundred milliwatts in the sun—enough to light LEDs or trickle-charge a small battery through a DC-DC board. We are specifically using a fully printable "carbon" perovskite solar cell architecture. This is the simplest, most robust starting point that avoids the need for expensive, specialized equipment like vacuum tools and metal evaporators. It's a technology that is not just used at the edge, but can be made at the edge.

We fully acknowledge such a micro-factory is effectively an infant-industrial lab. But this is where we have to start in-order to rebuild that missing-middle and eventually decentralize all the things!

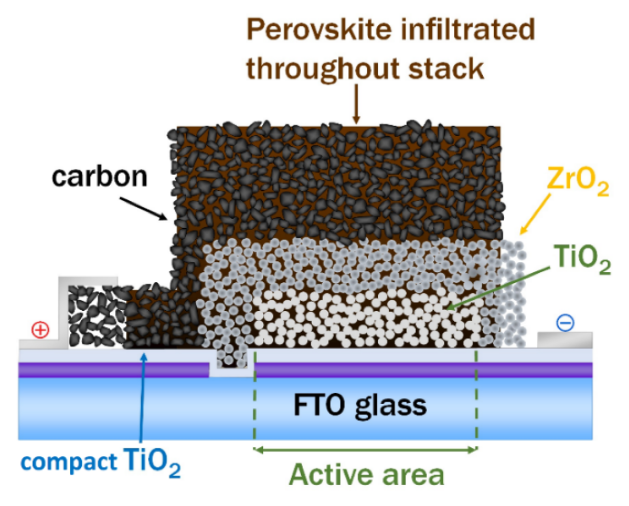

The Anatomy of Our Panel: What Each Layer Does

Before we build, let's understand the components. A solar panel is a sandwich of functional layers, and in our case, each one is critical:

- FTO Glass (The Foundation): This is our substrate. It's a clear sheet of

glass with a thin, conductive coating of fluorine-doped tin oxide (FTO). It

serves two functions: it lets sunlight in, and it acts as the front electrical

contact for our solar cell. We choose FTO over its cousin, ITO (indium tin

oxide), because it is more robust and can handle the high-temperature baking

steps in our process.

- TiO₂ Layer (The Electron Superhighway): This is a layer of titanium

dioxide, the same benign material found in sunscreen and paint. We print it as

a porous, sponge-like ceramic. Its job is to efficiently collect the electrons

that are generated when sunlight hits the perovskite.

- ZrO₂ Spacer (The Insulator): This is a layer of zirconium dioxide, another common ceramic. It acts as an insulating spacer, preventing the front and back electrodes from touching and short-circuiting the cell.

- Carbon Layer (The All-in-One Back Contact): This is a simple, printable "paint" made of carbon (graphite and carbon black). It serves as the top electrode, collecting the "holes" (positive charges) from the perovskite. Crucially, it's also porous, allowing the perovskite solution to be wicked into the stack from behind.

- Perovskite (The Engine): This is the light-absorbing layer. We introduce it as a liquid salt solution that soaks into the ceramic sponge and then crystallizes to form the active material that converts photons into electricity.

The Minimum Viable Microfactory: Your Bench Kit

You don't need a cleanroom or a multi-million dollar fabrication facility to start. Here is the essential, no-frills kit:

- Printing: A small, manual screen printer with a vacuum table, a steel

squeegee, and a set of stainless mesh screens. This is the same basic

technology used for printing t-shirts, adapted for high-precision electronics.

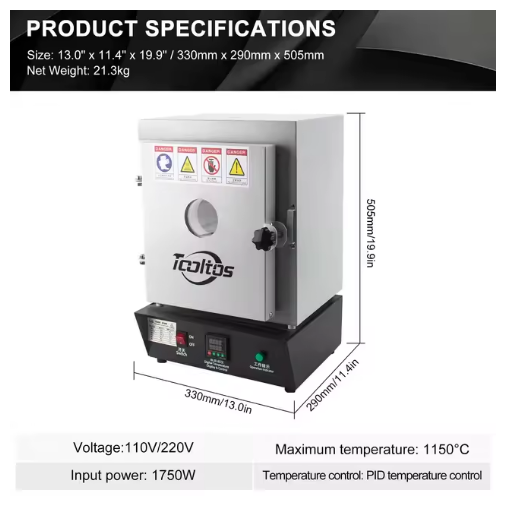

- Heat: A benchtop muffle furnace that can reach at least 500°C for

sintering the ceramic layers, and a standard lab hotplate for

lower-temperature steps.

- Wet Work: Standard laboratory glassware (beakers, pipettes), a precision scale for weighing chemicals, and essential personal protective equipment (PPE). A fume hood or a well-ventilated workspace is critical for safety.

- Testing: At a minimum, a multimeter to measure voltage and current. To properly characterize your cells, a small LED-based solar simulator and a USB buck/boost board are highly recommended.

The Shopping List: Sourcing Your Consumables

The materials for this process are surprisingly accessible and are not subject to the same strategic chokepoints as traditional silicon manufacturing.

- FTO Glass: Available from various online scientific suppliers, get the TEC15 variant.

- Pastes: You can purchase pre-mixed, screen-printable pastes for TiO₂, ZrO₂, and Carbon from specialized vendors. This is the easiest way to start.

- Perovskite Solution: You can buy pre-mixed perovskite inks or the individual precursor salts (e.g., lead iodide and organic salts like formamidinium iodide) and mix them yourself following established recipes. (Note: Lead is a hazardous material and must be handled with appropriate safety protocols.)

- Encapsulation: A roll of PIB (polyisobutylene) edge-seal tape and a second sheet of plain glass for the back. A hydrophobic topcoat can be added for extra moisture resistance.

- Contacts: Silver paint or conductive epoxy for making electrical connections, along with standard copper tape and wires.

The 10-Step Recipe: From Glass to Power

This is a simplified, step-by-step guide to fabricating a single 10x10 cm solar cell.

- Clean the Glass: Start with a thorough cleaning of the FTO glass substrate. A sequence of detergent, deionized water, and isopropanol is standard. From this point on, handle it only by the edges.

- Define the Active Area (Optional but Recommended): To improve performance, you can score the FTO coating with a glass cutter or a laser to define the precise area where you will print your cell. For your first attempt, you can skip this and print a simple rectangle.

- Print the TiO₂ Layer: Using your screen printer, apply a thin, even layer of the TiO₂ paste. Allow it to dry, and then sinter it in the muffle furnace for 30-60 minutes at 450-500°C. This burns off the organic binders and hardens the ceramic.

- Print the ZrO₂ Layer: Print the insulating spacer layer directly on top of the TiO₂. Dry and sinter it at a similar temperature.

- Print the Carbon Layer: Print the carbon electrode on top of the ZrO₂. This layer also needs to be dried and sintered, typically at around 400°C.

- Infiltrate the Perovskite: This is the magic step. Warm the printed stack on a hotplate to around 60°C. Then, carefully drop-cast the liquid perovskite solution onto the carbon side. The solution will be wicked into the porous ceramic stack via capillary action. Continue until the area darkens uniformly.

- Crystallize the Perovskite: Bake the cell on a hotplate at 80-100°C for several minutes. This drives off the solvent and allows the perovskite to form a high-quality crystal structure inside your scaffold.

- Make the Electrical Contacts:

- Front Contact: Carefully scrape a small area of the printed layers off one edge of the FTO glass to expose the conductive coating. Apply a small dab of silver paint or conductive epoxy and attach a piece of copper tape.

- Back Contact: Apply a small dot of silver paint onto the carbon layer (away from the main active area) and attach a tinned wire.

- Encapsulate the Cell: To protect your cell from the elements, run a strip of PIB edge-seal tape around the perimeter. Place a clean sheet of cover glass on top and apply gentle pressure and heat to create a seal.

- Test Your Creation: Take your finished module out into the sun! Measure the open-circuit voltage (Voc) and short-circuit current (Isc) with your multimeter. Connect it to a small load, like an LED, or use a boost converter to charge a 5V USB device.

What to Expect: "Working" vs. "World-Record"

Don't expect your first hand-made cell to match the performance of a commercial panel. The goal here is capability. A "working" first attempt will likely produce an open-circuit voltage of around 0.8-0.95V and a few tens of milliamps of current for a 10cm square cell. Achieving a practical efficiency of 5-10% is a fantastic first milestone with this architecture. While state-of-the-art research devices with this carbon-based structure have exceeded 20% efficiency, your benchtop result will be lower but incredibly valuable—it will be power that you made.

Safety and Sustainability: A Non-Negotiable Part of the Process

This process involves hazardous materials, specifically lead salts and solvents. A responsible microfactory operation must include:

- Lead Safety: All work with lead compounds should be done over trays to contain spills, and with appropriate PPE (gloves, eye protection).

- Waste Management: A dedicated, clearly labeled waste stream for all lead-contaminated materials (wipes, gloves, rinses) must be established. Do not pour these materials down the drain.

- End-of-Life Plan: From day one, have a plan for what to do with failed or end-of-life cells. This could involve encapsulation in resin for safe disposal or developing a protocol for recycling.

From a Single Cell to a Full Panel: The Path to Scaling

A single cell produces only about 1V. To create a useful panel, you need to connect multiple cells in series to increase the voltage. There are two ways to do this:

- Tile-and-Tab: The simplest method. You create multiple individual cells, as described above, and then wire them together externally with copper ribbon, like connecting batteries in a series.

- Monolithic Module: A more advanced technique where you use a laser or mechanical scriber to pattern the layers on a single, larger sheet of glass, creating series interconnections directly on the substrate.

Start with the tile-and-tab method. Once you have mastered the basic process, you can invest in the equipment needed for monolithic integration.

This is the essence of the perovskite wedge. It's not about replacing the entire global solar industry overnight. It's about providing a tangible, accessible, and powerful tool for communities to start building their own energy sovereignty, one printable panel at a time.

The point is to for the "decentralized community" to start getting into their hands dirty in the physical world, and start contributing and investing into the industrial commons. So that an adaptive ecosystem of physical world engineering becomes possible once more, and so that civilisation is not stuck in TINA mindset.

Yield Stacking the Second-Life Silicon Line

Silicon panels have a lifetime of 20 years. Within the next 20 years, there will be numerous existing solar panels that need to be recycled. Imagine what would be possible if these perovskite microfactories were combined with micro- recycling refineries for second life PVs. And with that, I leave you the reader with a combined diagram of the entire process flow above expanded with a potential future upgrade of refining second life silicon panels.